The mine complex

The mine complex is the group of surface facilities needed to operate a mine.

A tour route stretching from the square in front of the Wendel Miners Museum to the Wendel Mine explains the history of the complex, as well as the function and history of the main buildings that make up a “surface” mine.

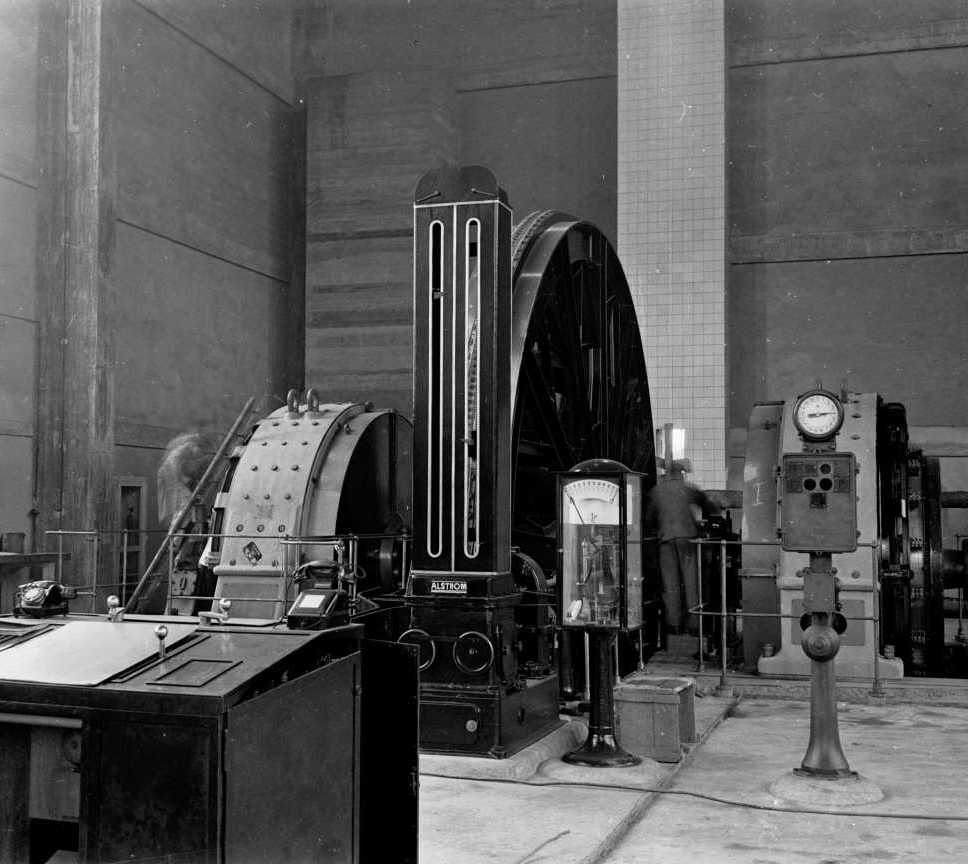

The route includes 10 trilingual terminals (French, German, English), placed near the buildings and illustrated with old photographs from the 1950s.